Seamless flooring by Nils Malmgren AB

Watch your floor!

Untreated concrete floor

These surfaces ponds, sucks in oil and other pollutants, has a poor chemical resistance, are difficult to keep clean, has a poor wear resistance, etc. To coat the concrete with something from Nils Malmgren AB flooring range, you do not need to watch your floor.

Finance and environment

Floor costs and environmental perspectives is proportional to the coatings expected lasting. Life expectancy is a function of product selection, and it is therefore important to choose the right.

Although the floor of the building belonging to the most essential elements, it may not be given enough time to find the best and most suited coating. Often times, it is due to ignorance and too much faith in the dealer’s glossy advertising brochures. You can never replace quality with long warranty periods.

Choosing flooring

To be able to determine the right product, one must be sure of the requirements specified for the floor, and be knowledgeable of the various products’ functions and properties.

The requirements one shall place for the floor are attained through a so called requirements analysis.

Such an analysis can include:

- Chemical stress

Chemicals that will come in contact with the floor coating should be known.

- Mechanical stress

Floors for truck traffic should never be thinner than 3 mm. For pedestrian traffic, it is often enough with 0.3 mm.

- Necessary layer thickness

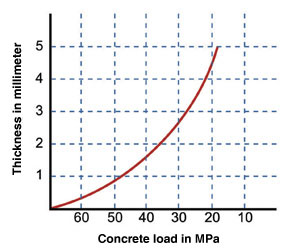

A floor covering’s layer thickness is primarily determined by two factors:

» Grain maximum, i.e., the largest filler.

» Load size in relation to the substrate.

Normally, the general rule applies that states that the minimum layer thickness shall be three times the grain maximum.

Normally, the general rule applies that states that the minimum layer thickness shall be three times the grain maximum.

Most epoxy coatings have very high compression strengths in comparison to concrete.

Floor concrete usually has a compression strength of 25–35 MPa, while an epoxy coating has a compression strength of 70–100 MPa. By increasing the layer thickness, the load can be distributed over a larger area of concrete. The distribution area’s size is shown in the figure below.

A 3 mm epoxy coating is sufficient under the condition that the coating has a compression strength that exceeds 70 MPa.

- Temperature variations

The floor’s temperature while in use, as well as local temperature variations, is important to know when choosing products.

- Anti-skid

Anti-skid, i.e. a certain roughness on the surface, is often on the wish list. In dry environments, it is usually unnecessary.

- Cleanability

Cleanability is often related to the degree of anti-skid.

- Freedom from pores

In the foodstuffs and pharmaceutical industries, there are naturally substantial demands for coatings being free from pores.

- Tightness

That tightness should be considered when planning is perhaps not entirely obvious. One often expects that an epoxy coating is tight, but so-called mortars of coloured sand and binding agent have, for reasons of application technique, too little binding agent.

- Levelness

A floor’s levelness is often of fundamental importance. Examples are high bay storage areas and floors for hovercraft.

- Reparability

Damages that occur because of impact, chemicals or increased temperatures cannot be avoided. It can be generally said that epoxy coatings are easy to repair.

- Classification to fire

Classification to fire (Euro Class) should be considered where necessary.

Procurement

When all parameters are known, it is time to contact the flooring dealer and discuss your floor.

You should make sure that the flooring can be carried out under the conditions prevailing in the workplace, such as temperature and moisture. Exceptions in the contract regarding damage caused by rising soil moisture should never be tolerated.

Moisture

Moisture in building construction can be a major problem for indoor environments. Moisture and alkali breaks down easily carpet glue and causes an unhealthy environment.

Moisture in building construction can be a major problem for indoor environments. Moisture and alkali breaks down easily carpet glue and causes an unhealthy environment.

We can offer complete systems for effective moisture, alkali and emission barriers.

These systems have been tested at testing institutes, and many years in the field have confirmed their function.

Our range

We have a wide range of epoxy products for floor and wall treatments.

Below are some examples.

- Impregnation

- Concrete sealers

- Thin layer coatings

- Self-levelling screeds

- Dry mortars

- Top-loaded screeds

- ESD-coatings

- Flexible coatings

- Lacquers

- Wall coatings

- Moisture barriers

- Injection

- Putty

- Rust protection

- Concrete glue

- Tank coatings

- After-glowing

More information

Please give us a call, +46 303 936 10